خطأ في تنسيق البريد الإلكتروني

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

The Future of Manufacturing: How Automated Robotic Systems Are Revolutionizing Industry

In today’s rapidly evolving manufacturing landscape, automated robotic systems are no longer a luxury; they are a necessity. With their ability to increase efficiency, reduce human error, and cut down operational costs, these systems are transforming industries across the globe. In this post, we’ll explore the features, benefits, and real-world applications of automated robotic systems, and how businesses can leverage them to stay competitive in a world where speed, accuracy, and innovation are critical.

What is an Automated Robotic System?

An automated robotic system consists of robots that are designed to perform tasks with minimal human intervention. These systems typically combine robotic arms, sensors, artificial intelligence (AI), and other technologies to carry out complex operations with high precision. Whether in manufacturing, logistics, or healthcare, these systems are engineered to optimize processes, streamline production lines, and ensure maximum efficiency.

Key Components of Automated Robotic Systems

Automated robotic systems are made up of several key components that work in synergy to deliver seamless automation. These include:

- Robotic Arms: These are the main moving parts that perform tasks such as assembly, picking, packing, and material handling.

- AI and Machine Learning: The software that enables robots to adapt to changing environments and make decisions based on data inputs.

- Sensors and Vision Systems: These help the robots detect objects, navigate spaces, and ensure that tasks are performed with precision.

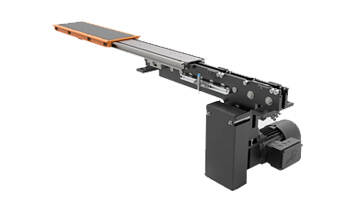

- Conveyor Systems: Often used in conjunction with automated robots, these systems move materials to and from robots in a manufacturing or distribution setting.

By combining these technologies, the robotic systems are capable of performing a variety of tasks that would otherwise be time-consuming and error-prone if done manually.

How Automated Robotic Systems Are Benefiting Industries

1. Increased Efficiency and Productivity

One of the primary advantages is their ability to enhance productivity. Unlike human workers, robots do not need rest or breaks, enabling them to work around the clock. They can also perform repetitive tasks with greater consistency, ensuring fewer errors and reducing the need for rework. This leads to faster production cycles and higher output rates, which are crucial in industries such as automotive manufacturing, electronics assembly, and food production.

2. Cost Reduction

While the initial investment in the robotic systems may seem high, the long-term cost savings are significant. By automating repetitive and labor-intensive tasks, companies can reduce labor costs and minimize errors that can lead to costly mistakes. Additionally, robots can often work in hazardous environments, minimizing the need for human workers to be exposed to unsafe conditions.

3. Enhanced Precision and Quality Control

The systems are designed to execute tasks with a high degree of accuracy. This is especially important in industries where precision is critical, such as electronics, pharmaceuticals, and aerospace. Robots can perform complex operations like welding, assembling tiny components, and sorting materials with extreme precision, reducing the chances of defects and ensuring that every product meets quality standards.

4. Scalability and Flexibility

As demand for products fluctuates, businesses need to be able to scale their operations up or down quickly. The systems offer the flexibility to adjust production capacity without the need to hire or lay off workers. For example, a manufacturing facility can easily reprogram robots to switch between different product lines or adjust to changes in production volume, allowing companies to remain agile in a fast-paced market.

5. Safety Improvements

In many industries, safety is a top priority. The robotic systems can operate in environments that would be dangerous for humans, such as high-heat or high-risk zones. For instance, robots equipped with thermal sensors can handle hot materials, while robots with heavy lifting capabilities can take on tasks that might cause injury if performed by humans. This shift not only protects workers but also improves operational efficiency by reducing downtime due to workplace injuries.

Real-World Applications of Automated Robotic Systems

1. Automotive Manufacturing

In the automotive industry, automated robotic systems have revolutionized production lines. From assembling car bodies to painting and installing intricate parts, robots now handle many critical aspects of vehicle manufacturing. The precision and speed of these robots allow for higher-quality vehicles to be produced in less time, meeting the demands of a competitive market.

2. E-commerce and Logistics

In the e-commerce sector, robots are being used in warehouses to automate order picking, packing, and sorting. Amazon, for example, uses thousands of robots in its fulfillment centers to move items around, reducing the time it takes to process orders. These systems can handle vast amounts of inventory and ensure that items are correctly picked and packed for delivery, increasing operational efficiency.

3. Healthcare

In healthcare, the robotic systems are being used in a variety of ways, from surgical assistance to medication management. Robotic surgery systems, such as the da Vinci Surgical System, allow surgeons to perform highly complex procedures with greater precision and less invasiveness. Additionally, robots are being employed in pharmacies and hospitals for tasks such as dispensing medication and delivering supplies, freeing up healthcare professionals to focus on patient care.

4. Food Processing

The food processing industry has also benefited from robotic systems, particularly in packaging and quality control. Robots can sort and package products such as fruits, vegetables, and packaged foods at a rapid pace, ensuring consistency and hygiene. These systems also help maintain a safer working environment by handling tasks that are typically messy or hazardous, like dealing with hot ovens or slippery surfaces.

The Role of China in Advancing Automated Robotic Systems

China has become a major player in the development and deployment of automated robotic systems, with its manufacturing sector leading the charge. The country’s robust industrial base, combined with advancements in robotics and artificial intelligence, has enabled it to become a global hub for automation technology. Companies in China are developing innovative solutions that integrate cutting-edge technology such as AI, machine learning, and advanced robotics to meet the growing demand for automation across various sectors.

Moreover, China’s expertise in manufacturing and logistics has positioned it as a critical supplier of components like China ground rail, which is an essential part of many automated systems, including robotic arms and conveyor systems. This infrastructure has helped lower costs and improved the accessibility of automated solutions for industries worldwide.

The Future of Automated Robotic Systems

As technology continues to evolve, the capabilities will only grow. We can expect to see even more advanced robots equipped with artificial intelligence, machine learning, and Internet of Things (IoT) capabilities. These robots will be able to perform more complex tasks, make decisions in real-time, and interact with their environment in ways that were once unimaginable.

The integration of 5G technology will also play a crucial role in the future of automation. With ultra-low latency and high bandwidth, 5G networks will enable robots to communicate and share data at lightning speeds, improving coordination and efficiency across production lines.

Moreover, we can anticipate a greater push toward collaborative robots (cobots) that work alongside humans. These robots will be designed with safety features that allow them to operate in close proximity to human workers, helping to enhance productivity while maintaining a safe work environment.

Conclusion

In conclusion, automated robotic systems are not just a trend—they represent the future of manufacturing, logistics, healthcare, and more. With their ability to increase efficiency, reduce costs, and improve precision, these systems are changing the way industries operate on a global scale. As businesses continue to adopt automation technologies, the role of robots in everyday processes will only become more critical, paving the way for a more efficient and productive future.

By leveraging the power of robotic systems, industries can stay ahead of the competition and meet the ever-growing demands of today’s fast-paced market. Whether it’s automotive manufacturing, e-commerce, or healthcare, the future is undoubtedly robotic.