خطأ في تنسيق البريد الإلكتروني

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Exploring the Role of a Metal Gear Company in Today's Industrial Landscape

In the world of mechanical engineering, precision and reliability are key. One of the most crucial components in a variety of industries is the metal gear, which plays an essential role in machinery and mechanical systems. Whether you're working in automotive manufacturing, robotics, or heavy industrial machinery, a trusted metal gear company can be the difference between smooth operations and costly failures.

In this blog post, we will dive deep into the importance of a metal gear company, the processes involved in manufacturing metal gears, and why businesses around the world trust these companies for their mechanical needs. Additionally, we'll take a closer look at how factors like innovation, quality control, and manufacturing location—such as China’s role in producing China ground rail—shape the global metal gear market.

What is a Metal Gear?

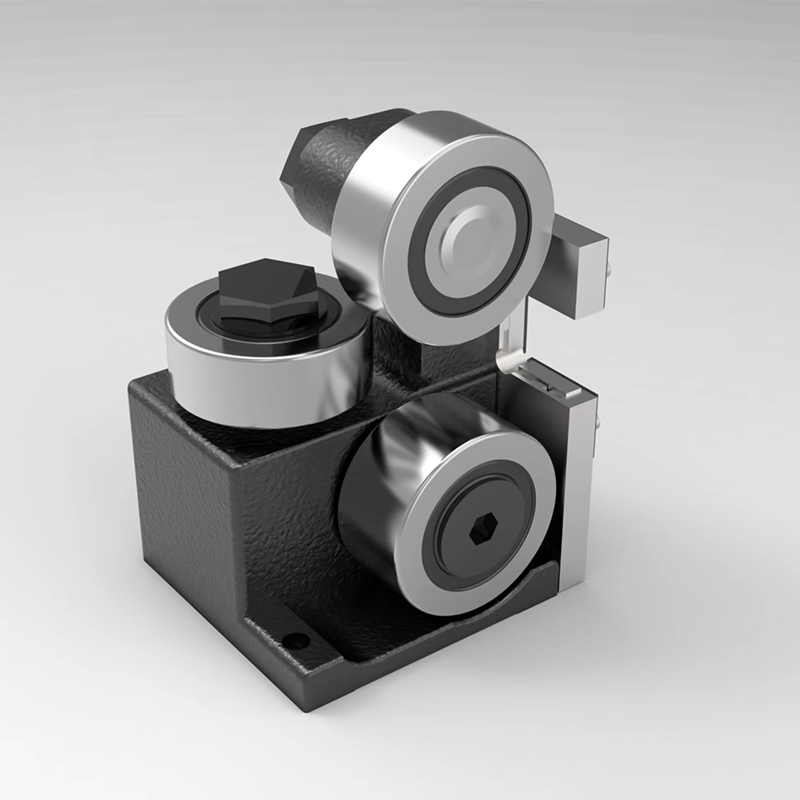

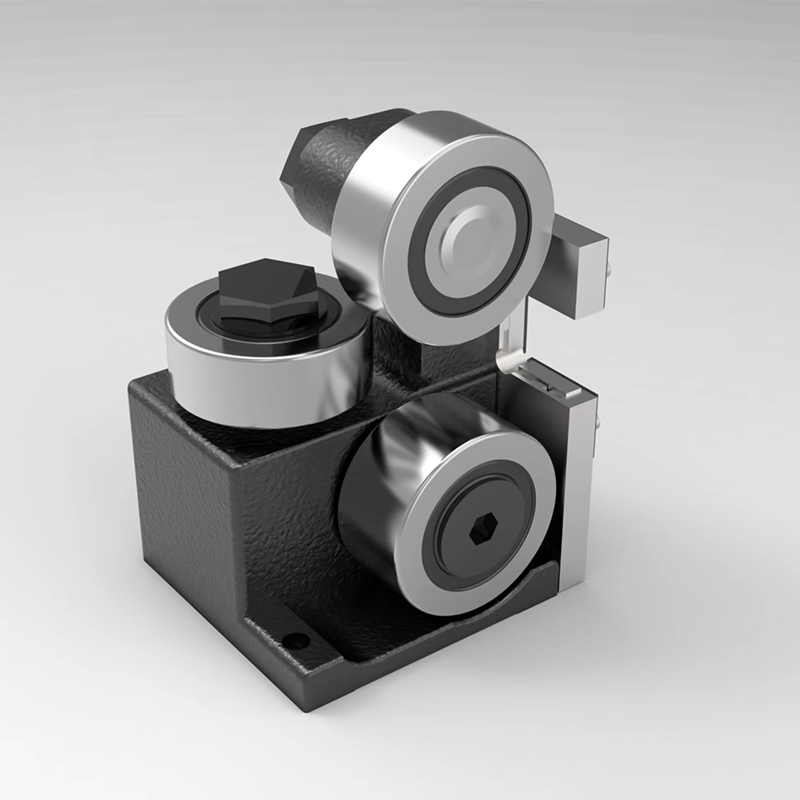

Before diving into the details, let's take a moment to define what a metal gear is. A metal gear is a mechanical component with teeth that mesh with the teeth of another gear to transmit motion and torque. These gears are made from a variety of materials, including steel, brass, and other alloys, and are used in a wide range of machinery.

These gears are essential in applications that require high durability and the ability to withstand heavy mechanical loads, such as in automotive gearboxes, industrial machinery, and even in more specialized sectors like aerospace and robotics.

Why Businesses Choose a Reliable Metal Gear Company

When it comes to sourcing metal gears, businesses must ensure they are partnering with a reliable company. There are several reasons why companies need to choose wisely when selecting a manufacturer for their metal gears:

-

Precision Engineering

Metal gears need to be manufactured to exact specifications. A leading company invests in high-precision machinery and employs skilled engineers to ensure that every gear meets strict quality standards. -

Durability and Longevity

A high-quality metal gear must be durable enough to handle heavy usage without failure. Whether it's for automotive applications or for industrial machinery, durability is a top concern. Choosing the right company ensures that the gears produced are made from the best materials and are designed to last. -

Customization Options

Different industries and applications require different types of gears. A company can offer customization options to meet specific needs, such as unique sizes, materials, or teeth designs. These custom gears ensure that the machinery performs optimally in its respective application. -

Competitive Pricing

Cost is always an important factor when purchasing industrial components. A reliable company offers competitive pricing, helping businesses get the quality gears they need without going over budget.

The Role of Technology in Metal Gear Manufacturing

The production of metal gears has evolved significantly with the advancement of technology. Traditionally, metal gears were manufactured through manual machining processes, but today, modern technologies like CNC machining and 3D printing have revolutionized the industry. Here's how these technologies are enhancing gear production:

-

CNC Machining

Computer Numerical Control (CNC) machining has enabled metal gear companies to produce highly accurate gears at a faster pace. This precision manufacturing method allows for the creation of intricate gear shapes with a high level of consistency, which is crucial for ensuring smooth operations in complex systems. -

Additive Manufacturing (3D Printing)

In some cases, 3D printing is being used to produce gears that are not only lightweight but also optimized for performance. While this technology is still relatively new in the metal gear industry, it has the potential to revolutionize the way gears are designed and produced, particularly for specialized or low-volume applications. -

Simulation Software

Simulation software helps metal gear companies test designs before physical production begins. This software simulates how gears will interact under various conditions, which helps manufacturers optimize their designs for strength and performance.

Key Industries That Rely on a Metal Gear Company

Metal gears are used across a wide range of industries. Let's take a look at some of the key sectors where metal gear companies play a crucial role:

1. Automotive Industry

In the automotive industry, metal gears are essential for transmissions, differentials, and other mechanical systems. The metal gear company must produce gears that can handle high levels of stress and torque, ensuring smooth operation and long service life.

2. Aerospace and Defense

The aerospace industry relies heavily on metal gears for critical applications, including landing gear, engines, and flight control systems. Precision and reliability are paramount, and a leading metal gear company ensures that these gears meet stringent safety and performance standards.

3. Industrial Machinery

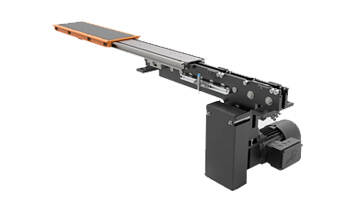

Heavy industrial machinery like cranes, conveyors, and mining equipment all rely on high-quality metal gears. These gears need to be able to endure harsh conditions, including extreme temperatures and heavy loads. A reputable company ensures that these gears can stand up to the challenge.

4. Robotics and Automation

In the world of robotics and automation, metal gears help drive movement in robotic arms, motors, and other mechanical systems. These gears must be lightweight yet durable, and they often need to be custom-designed for specific robotic applications. Robotics companies turn to specialized metal gear companies to meet these requirements.

5. Energy and Power Generation

In energy production, metal gears are used in wind turbines, generators, and other mechanical systems that convert energy. These gears must be designed for optimal efficiency and longevity to ensure the continuous operation of energy production systems.

China’s Role in the Global Metal Gear Industry

When it comes to metal gear manufacturing, China is one of the largest players in the global market. The country is home to a significant number of metal gear companies that cater to industries across the world. China has become a major hub for manufacturing due to its competitive labor costs, access to raw materials, and robust manufacturing infrastructure.

One important component of metal gear systems in industries such as rail transport is the China ground rail system. This ground rail is critical for providing the necessary support for heavy equipment and machinery in rail systems, where metal gears are often used for track maintenance and operations. A metal gear company based in China can offer highly efficient manufacturing solutions, ensuring that such systems function smoothly and reliably.

The Future of Metal Gear Manufacturing

Looking ahead, the metal gear industry is expected to evolve with new trends and technologies that enhance both performance and efficiency. Here are some trends that may shape the future of metal gear companies:

-

Advanced Materials

The development of new alloys and composite materials could allow metal gear companies to produce gears that are even more durable and lightweight than current models. -

Automation and AI

As automation and artificial intelligence become more integrated into manufacturing processes, metal gear companies will be able to optimize production, reduce waste, and enhance quality control. -

Sustainability

In response to global sustainability concerns, metal gear companies are beginning to focus on eco-friendly production practices. This could include using recycled materials, reducing energy consumption, and minimizing waste during manufacturing. -

Integration with IoT

The rise of the Internet of Things (IoT) means that metal gears could soon be embedded with sensors that monitor their condition in real-time, alerting users to potential issues before they cause a failure.

Conclusion

A metal gear company is a vital partner for industries around the world that rely on high-precision mechanical components. From automotive to aerospace, industrial machinery to robotics, these companies play a crucial role in ensuring that complex systems operate smoothly and efficiently. With advancements in technology and manufacturing processes, metal gear companies are poised to continue driving innovation in the field.

Whether you're sourcing gears for heavy-duty equipment or designing a custom solution for a specialized application, partnering with a reputable metal gear company ensures you’re getting the best in terms of quality, reliability, and performance.